What Is Digital Printing?

Digital printing Service differs from traditional, analog printing methods–such as offset printing–because digital printing machines do now not require printing plates. Instead of the usage of metallic plates to switch an image, digital printing presses print the picture without delay onto the media substrate.

Digital production print technology is evolving quickly, and digital printing output quality is improving continuously. These advancements are delivering print first-rate that mimics offset. Digital printing allows extra advantages, including:

*personalized, variable data printing (VDP)

*print-on-demand

*cost-effective short runs

*fast turnarounds

What Is Offset Printing?

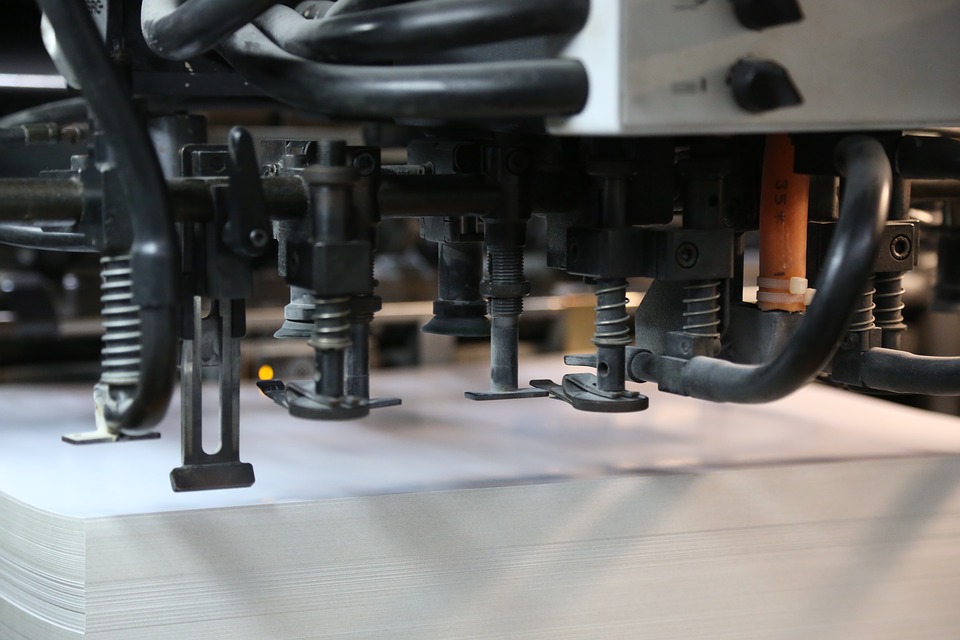

Offset printing is a commonly used printing technique where the colored image is transferred (or “offset”) from a plate to a rubber blanket and then to the printing surface. When used in combination with the lithographic process, which is based on the rejection of oil and water, the displacement technique uses a flat image carrier (planographic). The ink rollers transfer ink to the image area for image carriers, while a roll of water applies a water-based film to the blurry areas.

The modern “tape” process feeds a large roll of paper through a large multi-part press machine, usually several meters, which then prints continuously as the paper passes.

Both kinds of printing produce print merchandise that is extremely excessive in quality and suit for professional high-quality printing for businesses. The key elements that make customers pick out one over the other are usually the quantity of the print mission and area of interest task requirements.

There are several differences—such as color abilities and sheet sizes that fluctuate between offset printing versus digital printing.

Technologies Used in Offset Printing V/s Digital Printing

The technical difference between offset printing and digital printing is the way images are exchanged on paper. This difference affects the economics of operating costs of these machines, and this difference in price is passed on to the printing consumer.

The offset printing uses sculptural metal plates that apply ink to a sheet of paper. Setting up for offset printing is usually more time consuming and expensive than digital printing. Metal plates should be applied to the rollers where the ink is transferred to a plate carved paper for each color used. Then, press on the sheets of “scrap” paper for a few minutes until the plates are properly inked; Think of it as “warm warm warm warm” sheets that gradually pull.

Digital printing can easily print a sheet of paper or a copy of a brochure with minimal installation. However, offset printing requires a considerable amount of extra installation time and materials. Any ink sheet that comes from an offset press is actually cheaper than a digital press, but it only makes sense if the print job is high enough.

Also – this is the number of copies to count; Not the total number of sheets. Offset only makes sense if you make thousands of copies of the same sheet. For example, if you print 500 copies of a 100-page directory, you will print 50,000 pages, but only 500 copies. This is classified as “short-term printing.” (Offset does not make sense since each sheet must have its own plate.)

Differences between offset printing V/s digital printing

The first of these differences is the size of the sheet.

Digital printing generally runs sheets of smaller sizes, typically 19 “sheets with some machines up to 29”. Offset printing, on the other hand, generally runs 29 “and 40” presses. This increase in size occasionally allows some types of printing that is not possible on smaller sheets. Some examples include posters, books that require large covers and certain types of brochures.

When the size of dimensional printing is important, but print volumes do not deserve the use of an offset press, customers often resort to large-format digital presses for printing short runs. There are some cases of large format printing that cannot be done on large format digital presses, such as certain types of printing surfaces such as packaging materials, plastics, etc.

The second of these differences is the representation of the color.

Each printing equipment offers slightly different interpretations and controls on how colors are applied on a page. Offset presses can provide certain color controls that are superior to digital printing. For example, printing color tones (a color management system) is more accurate in offset presses because they actually use Pantone ink. This is more typically important for large corporate brands for which the consistency of color is worth a considerable amount of money.

The third of these differences is that digital presses are significantly cheaper for quick response projects.

Digital printing offers incredible response times due to the significantly shorter setup time. Stores that make a good digital print can offer a print the same day and the next day much more efficiently and economically than those with offset printing. For example, it would make sense to launch a project on several digital presses that require minimal configuration. On the other hand, launching it in multiple offset presses would require multiple plates and time to ink the plates correctly.